Commercial Cooler &

Freezer Deep Cleaning

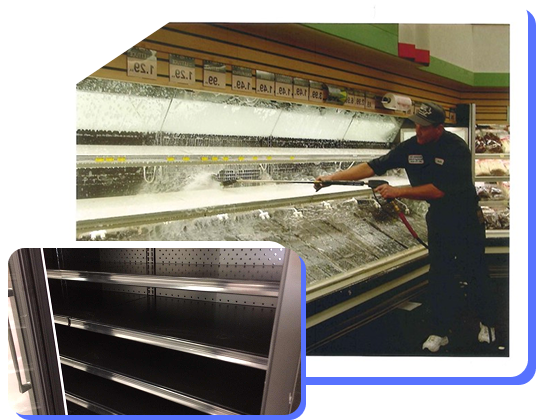

Comprehensive commercial refrigeration cleaning services that ensure food safety, extend equipment life, and maintain health code compliance for all types of coolers and freezers in commercial food service facilities.

The SDI Advantage

Commercial refrigeration units are critical food storage areas that require specialized cleaning to prevent contamination, mold growth, and health code violations. Walk-in coolers, freezers, produce coolers, aisle coolers, and display cases accumulate food residues, spillage, mold, and microbial growth that standard cleaning procedures can’t effectively address. SDI’s professional commercial refrigeration cleaning services provide thorough sanitization using specialized techniques and antimicrobial treatments. Our experienced technicians clean all surfaces, components, and equipment to eliminate contaminants, improve operational efficiency, and ensure your facility meets stringent health department requirements across California, Nevada, and Arizona.

Our Commercial Cooler & Freezer Deep Cleaning Includes:

Complete disassembly and cleaning of shelving units

Wall, ceiling, and floor deep cleaning and sanitization

Evaporator coil and fan cleaning

Drain line cleaning and treatment

Door gasket cleaning and mold treatment

Condenser coil cleaning (external units)

Detailed documentation for health inspection compliance

Strip curtain cleaning

Why Choose SDI:

Specialized equipment designed for cold storage environments

Food-safe, commercial-grade sanitizing solutions

Temperature-appropriate cleaning methods

Minimal food product displacement during cleaning

Health code compliance expertise

EPA-approved antimicrobial treatments

Detailed before/after documentation

Flexible scheduling to minimize operational disruption

SDI Results:

Process

Our Commercial Refrigeration

Cleaning Process

01

Initial Assessment

Comprehensive inspection of all refrigeration units to identify problem areas

02

Preparation

Coordination with staff for food storage relocation or containment

03

Temperature Management

Safe adjustment of temperature settings for effective cleaning

04

Systematic Cleaning

Unit-by-unit approach based on refrigeration type and requirements

05

Component Cleaning

Detailed cleaning of coils, fans, drainage systems, and moving parts

06

Sanitization

Application of food-safe antimicrobial treatments to all surfaces

07

Reassembly

Careful restoration of all shelving, displays, and equipment

08

Temperature Reset

Return to proper operating temperatures

09

Final Inspection

Quality verification across all cleaned units

10

Documentation

Comprehensive before/after photos for your records

Raving Fans

Client Testimonials

Restaurant Owner

Hotel Food Service Director

Services Areas

Serving commercial food service facilities throughout California, Nevada, and Arizona, including restaurants, grocery stores, hotels, hospitals, schools, universities, and food distribution centers.

Danny Quiroz

Director of Operations

800-794-2345

10251 Trademark Street Suite B Rancho Cucamonga, CA 91730

Contact US

FREQUENTLY ASKED QUESTIONS

How often should commercial refrigeration units be deep cleaned?

Most health departments recommend professional deep cleaning at least twice per year for walk-in units, while display cases and produce coolers may require quarterly service due to higher customer exposure. High-volume operations or units with recurring issues may benefit from monthly maintenance. We can determine the appropriate frequency based on your specific operation and unit types.

Will food need to be removed during cleaning?

We work to minimize product displacement by cleaning in sections and using containment methods. For walk-in units, some temporary storage may be necessary, while display cases can often be cleaned during off-peak hours with minimal disruption. During consultation, we'll develop a plan that protects your inventory while ensuring thorough cleaning.

Can you service all types of commercial refrigeration equipment?

Yes, our technicians are trained to work with walk-in coolers and freezers, produce coolers, aisle coolers, display cases, deli cases, and various specialized refrigeration units. We use appropriate cleaning methods and solutions for each equipment type and manufacturer.

How long does the cleaning process take?

Service time varies by unit type and quantity. Walk-in coolers typically take 4-8 hours, while display cases and produce coolers can often be serviced in 1-3 hours each. We provide detailed time estimates during consultation and offer overnight and off-hours scheduling to minimize operational disruption.

HAVE QUESTIONS? WE HAVE ANSWERS.

Contact our commercial cleaning experts for free consultations, custom quotes, and professional advice tailored to your facility.